TEST and Validation

Steering and Suspension: Crucial Safety Components for Commercial Vehicles

Ensuring safety in the realm of commercial vehicles requires a rigorous validation process. This process entails defining a comprehensive set of methodologies and tools aimed at verifying whether our product designs align with both regulatory and technological requirements. Such verification stands as a foundational pillar for the secure deployment of Original Equipment Manufacturer (OEM) and Independent Aftermarket (IAM) parts. These methodologies and tools must take a holistic approach, addressing the entire vehicle chassis.

Our Approach: Holistic Testing Expertise

We adopt a holistic approach by forging close collaborations with our customers' engineering departments throughout every phase of the development journey. Leveraging our extensive expertise, garnered over years of experience, and our cutting-edge test bench research and development center, we prioritize safety and reliability as our core values.

Pushing the Limits for Unwavering Confidence

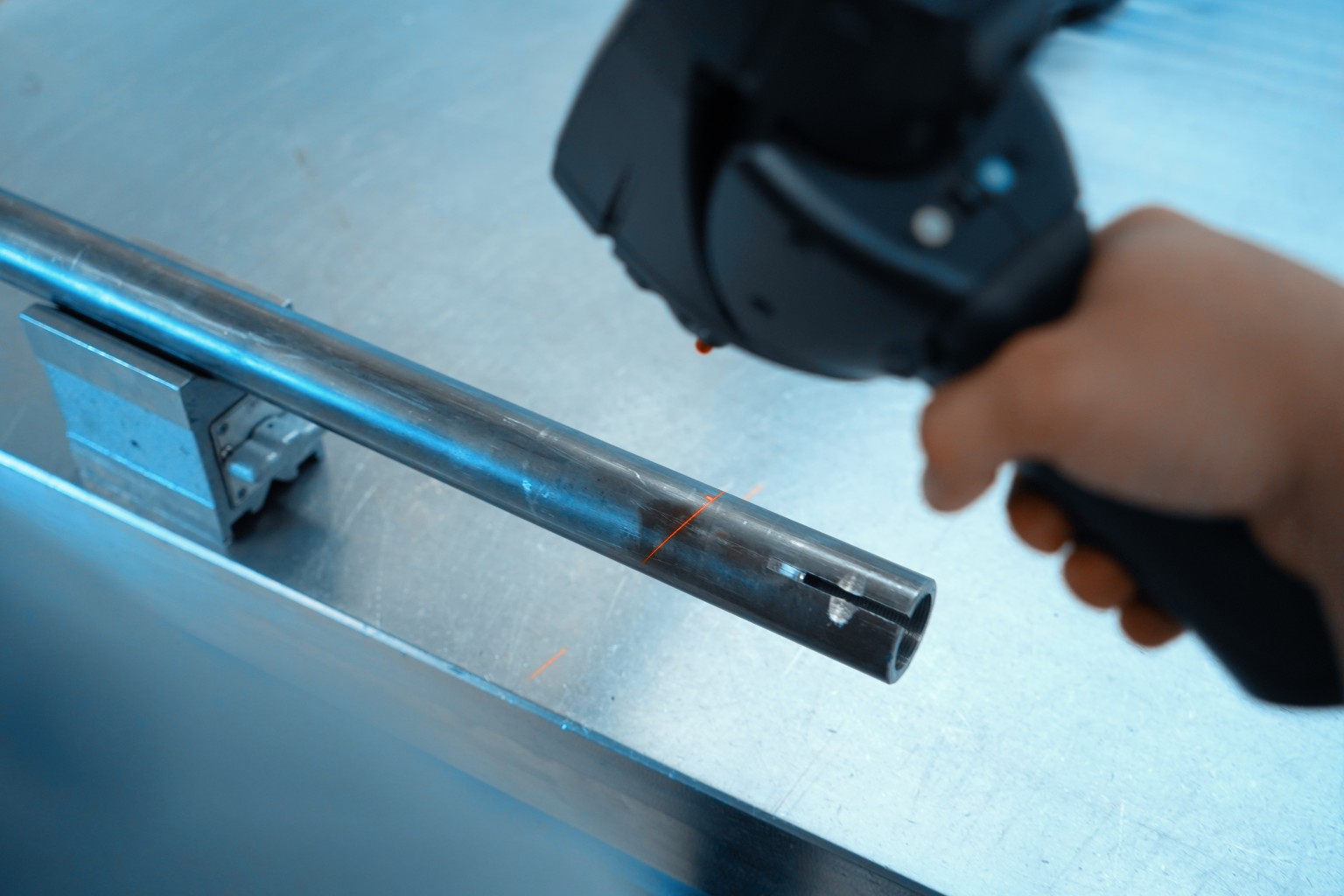

Our commitment to safety means subjecting all our parts to rigorous testing, surpassing their reasonable limits. This dedication ensures that drivers can place full trust in their vehicles at all times.

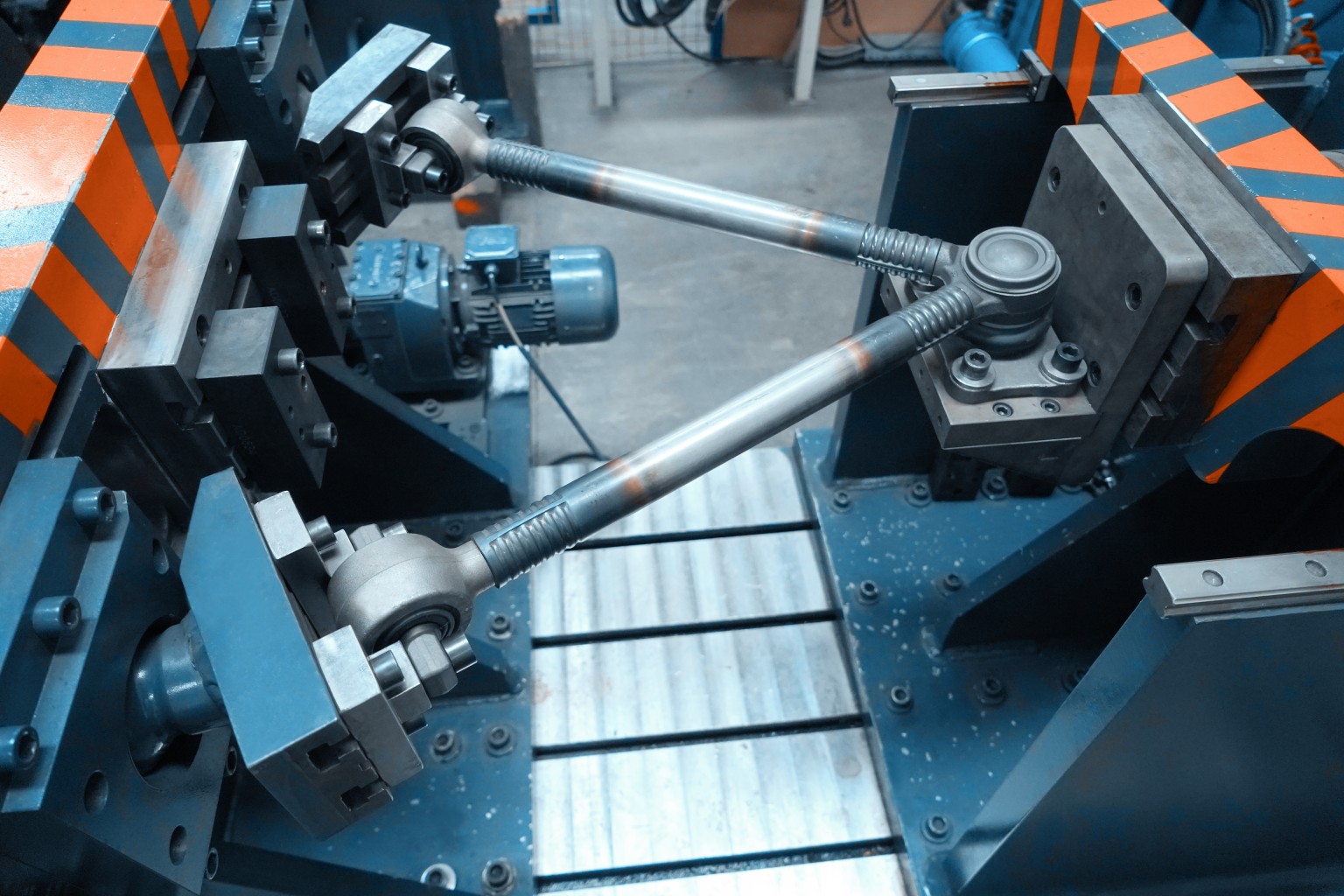

Our In-House Testing Capabilities Cover:

Axial, Radial (Backlash), and Torsional Elasticity

Rotational Ability

Articulation

Breakaway Torque

Pull and Push-Out Forces

Four-Axial and Fatigue Testing

Salt Spray Testing

Leakage and High-Pressure Air Tank Testing

Boot Testing, Dirt Resistance, Sealing, Creep, and Endurance

We conduct wear, fatigue, functional, and rubber tests, leaving no stone unturned to guarantee that BAGEN parts can withstand any conditions they may encounter.